#Industry News

The Safest Corrosion Gauge for ALL Hazardous Gas Zones

Gas explosions are often catastrophic, causing irreversible damage and sadly, human fatalities.

Gas explosions are often catastrophic, causing irreversible damage and sadly, human fatalities. When an ignition source, such as electrical or thermal equipment, enters a space where there are flammable and potentially explosive substances, typically in a confined building or vessel, extreme heat increases pressure in the space and causes an explosion. Working environments which manage these risks on a daily basis are:

• Oil and gas refineries

• Chemical plants

• Hazardous storage tanks

• Fuel depots

• Road tankers

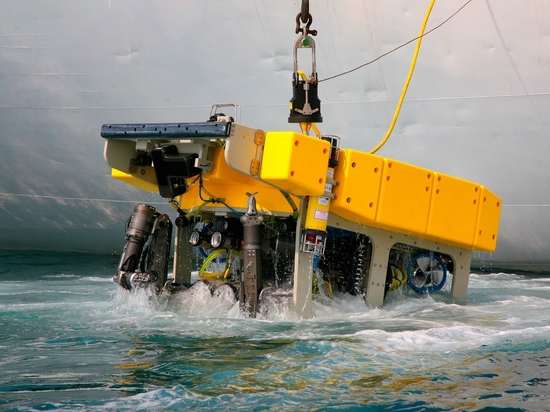

• Chemical, oil and gas tankers

• Industrial processing facilities in explosive atmospheres.

There are many ignition sources that may be brought into these areas for various reasons. One of these reasons performs a rather crucial task – ultrasonic testing equipment designed to carry out essential maintenance checks on the machinery operating to these processes. Whilst maintenance is vital to the safety of these areas and can even contribute to prevention of explosions by preventing leakage, the maintenance equipment itself needs to be safe to handle in these hazardous environments.

How can Cygnus 1 Ex help?

The Cygnus 1 Ex is certified safe to use in locations where there is a risk of fire or explosion due to the presence of ignitable or flammable substances in the air at concentrations high enough to produce an ignitable mixture. This includes gases, vapours, and dust.

This is because Cygnus 1 Ex is Intrinsically Safe. For any equipment like Cygnus 1 Ex, that contains electronic components including batteries, intrinsic safety technology limits the energy present in a system, meaning no arc or spark can be generated, and no component can heat up enough to ignite a hazardous atmosphere under any conditions. This applies under both normal use and with applied fault conditions, at low power levels, and low stored energy.

Cygnus 1 Ex has an Intrinsically Safe Design, featuring:

• Limited output energy to prevent ignition of explosive atmospheres

• Anti-static enclosure to prevent static electricity discharge

• Multiple redundant safety components

• In the event of damage or a fault, no high surface temperatures are generated that could ignite an explosive atmosphere.

‘Intrinsically Safe’ is an Ex-Protection Concept, used to determine which areas of a facility (‘zones’) the equipment is suitable for. The term ‘Ex’ is recognised globally when referring to explosive atmospheres and the schemes used to prevent explosions. In both IECEx, ATEX and North American systems, intrinsically safe equipment can be used in any Zone or Division with the correct equipment protection level.

Cygnus 1 Ex is the ONLY gauge of its kind in the world that meets the highest classification of ATEX Zone 0, which is equivalent to NEC (UL) Class I Division 1 Group “ALL”. Zone 0 is defined as ‘a place in which an explosive atmosphere is present continuously or for long periods. It is also certified to Zone 1; ‘a place in which an explosive atmosphere is likely to occur in normal operation occasionally’ and Zone 2; ‘a place in which an explosive atmosphere is not likely to occur in normal operation, but if it does occur, will persist for a short period only’.

Plants and facilities will have many different Divisions or Zones, and once these hazardous areas have been established, signs must be installed to warn and inform anyone entering the area. It is important to be aware that these area labels can change, especially, for example, as a result of a leak. If a welded joint, flange or valve is leaking, the Zone around it can be elevated from Zone 1 to Zone 0.

More first-class Cygnus 1 Ex features

The Cygnus 1 Ex ultrasonic thickness gauge offers an invaluable leap forward for safe structural inspection in hazardous areas. Reviewed as “versatile, multifunctional, robust and intuitive,” by our customers, this intrinsically-safe gauge provides first-class user control and flexibility, eliminating the need for plant shutdown or a Hot Work permit. Equipped with 3 measuring modes and a selection of probes, the gauge can measure a range of materials and metals with severe corrosion or protective coatings up to 20mm thick. This saves considerable time and money removing coatings!

The great news for advanced users is that the Manual Measurement Mode ensures measurement on trickier areas, like heavy corrosion, is easier and more accurate, thanks to more versatile settings. Like a flaw detector, you can manually adjust two gates, positioning them anywhere on the A-scan, alter gate height, start-point and width, and measure from a gate or between gates. Furthermore, Time-Controlled Gain (TCG) enables introduction of different gains to boost weaker echoes.

When storing and analysing data, you’ll enjoy equal flexibility. Comprehensive data logging offers linear, templates, and 2-D or 3-D grid formats, with 16 grid patterns and annotation capability. Radial Points enable further investigation on areas of interest or heavy corrosion, allowing you to add up to 12 additional measurements ‘around’ the principal measurement.