#Product Trends

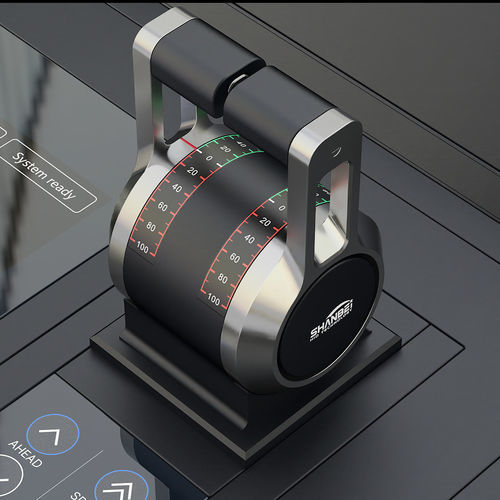

Design elements of Marine steering wheels

Marine steering wheels are the core operating components for ship course control. Their design needs to take into account functionality, safety, human-machine adaptability and environmental reliability.

I. Ergonomic design

1. Size matching: Match the operating posture (standing/sitting) according to the ship type (30-50cm for small and 80-120cm for large).

2. Operating Experience: The handle is anti-slip (rubber/textured metal) and fits the palm well. The operating force and stroke are reasonable, reducing fatigue.

-----------------------------------------------

II. Structural and Performance Reliability

1. Material selection: The frame is made of high-strength alloy (anti-rust), and the handle is made of durable and anti-slip material.

2. Connection strength: The connection parts such as the drive shaft are precisely stable, resistant to vibration and wear, and prevent deformation.

-----------------------------------------------

III. Scene Adaptability

1. Servo matching: Compatible with different servo types such as hydraulic, electric, and manual.

2. Ship type compatibility: Single steering wheel for small ships, double steering wheel/emergency steering wheel for large ships; The installation space does not conflict with the equipment on the cab.

-----------------------------------------------

IV. Environmental Adaptability

1. Anti-corrosion: Anti-rust treatment of metal parts (chrome plating/painting) to resist salt spray.

2. Weather resistance: Resistant to high and low temperatures (-30℃ to 60℃), and resistant to jolting and vibration. The electronic components are waterproof and dustproof (IP56+).

-----------------------------------------------

V. Safety Design

1.Redundancy guarantee: Equipped with emergency brake and spare steering wheel (for large ships).

2. Protection mechanism: Overload protection (to prevent component damage) Real-time display of rudder Angle and audible and visual alarm in case of abnormality.