#Industry News

ODC Marine and MARINELEC innovate in electric propulsion system monitoring

A partnership of trust for a French made solution

The market for electric propulsion vessels operating in sensitive environments, inland navigation and marine protected areas is booming. This represents not only a reduction in the ecological footprint of maritime and fluvial transport, but also a change in technology. These state-of-the-art vessels, which integrate increasing amounts of equipment to ensure safety and comfort on board, are also more complex and require the monitoring of a whole host of data. To simplify access to information from the bridge and to enable the captain to make the right decisions to protect his or her passengers and crew, ODC Marine shipyards have called upon MARINELEC Technologies to develop a unique interface which gathers together all the information and commands of the vessel to be monitored.

A partnership of trust for a French made solution

MARINELEC Technologies and ODC Marine have jointly specified and developed the Supervision monitoring system for hybrid and electric vessels built by the yard. “All the safety equipment of our vessels is built and provided by MARINELEC Technologies which is our long-standing partner,” explains Stéphane Gonnetand, associate director of the yard who points out that although it is based in China, the company remains French and endeavours to export French know-how and components.”The interface which we require is strategic. It gathers together all the information concerning the vessel. It was essential to develop a system with a trusted partner who knows the constraints of the marine environment and has the best expertise in terms of norms. MARINELEC Technologies already has monitoring systems which group together all safety systems. We also wanted to centralise the information that concerned our vessels, including the equipment linked to the electronic propulsion. We started on our first hybrid vessel about two years ago and today we have managed to standardise the architecture of the new system which can evolve to suit the specific nature of each new vessel, according to the needs of the owner; what is different today is the power of the computer and the bridge monitor.”

Communication protocols suited to electronic propulsion

MARINELEC Technologies monitoring products are « customisable » and can be tailored to different monitored vessels. Electric shipping involves the monitoring of new equipment such as battery banks or chargers, developed originally for land-based industry. They use communication systems such as CAN, which are extremely good at avoiding electromagnetic disturbance, and are not so usual in marine electronics but widespread when it comes to electronic propulsion:

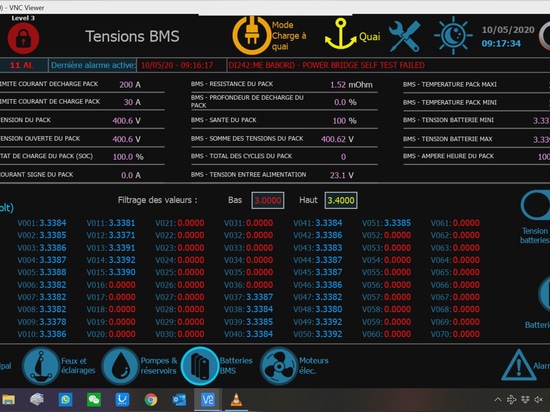

« We had to adapt the communication protocols of our systems so that they were compatible with the vessel’s electric systems » explains Jean-Marc Autret, head of MARINELEC Technologies design office. “ Electronic propulsion, that is to say the electric engine or engines, the chargers or the battery bank composed of multiple cells, generate complementary information and thus every parameter has to be monitored: battery voltage, current and temperature; engine speed, current, torque and temperature, etc. We have incorporated specific components that were selected paying careful attention to ensure that they conform to the safety and quality standards that are applicable in the maritime sector. With our correspondent Jean-Benoît Delpy, based in China, we were able to organize technical discussions with manufacturers all over the world, to understand how the Battery-Power Management System worked. This flexibility and technical knowledge have enabled new equipment to be incorporated in MARINELEC Technologies monitoring systems which are still way ahead of the market today.”

Charger and electric battery manufacturers also communicate via a CAN interface. However, they use protocols which are specific to their own equipment to which, thanks to its expertise, MARINELEC Technologies has succeeded in adapting its automata program. For the CAN physical communication interface, the design office worked on the NMEA 2000 standardised protocol which is being increasingly adopted by engine manufacturers. This research and development initiative has led to MARINELEC Technologies being able to tailor its automata programs to any request for features using this norm.

Meanwhile, in the shipyard, ODC Marine modified the design of all the vessel’s electrics to optimise monitoring. Using the CAN bus enabled the ship’s cable to be lightened “by about 30%” Stéphane Gonnetand assures us. The multiplexed communication enables several data to travel along just two wires. “This saving has been reinvested in extra acoustic insulation and comfort for the crew. This has also enabled the yard to standardise network architecture. We have already delivered 5 vessels and 3 others are being built, all equipped with these systems and each time incorporating new equipment. Whether we plug the component in or not, it is still the same architecture. That is a significant saving in engineering” adds the yard’s Associate Director.

An intuitive, efficient, high-performance system

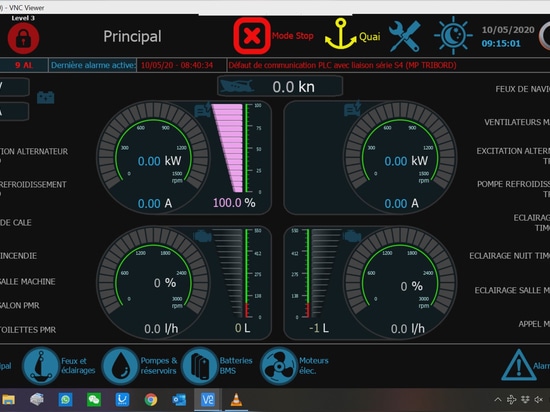

MARINELEC and ODC Marine have sought to make the system as easy as possible for a crew which has no experience of a hybrid vessel. MARINELEC has developed specific programs for its automata and also an ergonomic and intuitive interface with a touch screen and easy-to-identify pictograms. At a glance, the captain can see the state of the vessel’s critical systems which are all connected to the monitoring system.

This wheelhouse system is composed of a touch screen – a highly resistant computer (human-machine interface) – which interacts with an automaton housed in a compartment formed of electronic cards communicating with a CAN bus network or directly with a system. Here, we are talking about equipment with an in-service life of tens of thousands of hours. The objective was to improve safety and facilitate decision-making by alerting the vessel owner in real time to any anomaly by means of an alarm. All MARINELEC Technologies monitoring systems are proactive, activating upstream of any breakdown or incident. This ensures the safety of equipment and crew and the optimisation of maintenance.

A maintenance optimisation tool

The system also enables the maintenance of increasingly complex and communicating vessels and equipment to be improved. MARINELEC systems enable the many alarms of these recent technologies to be managed. A single interface centralises all the information and, by making it intelligent, preventive maintenance can be carried out. This is crucial for hybrid vessels with battery banks, cooling pumps and electric motors which all need special attention to ensure a longer in-service life. MARINELEC has thus developed specific preventive maintenance features, such as time meters and pre-failure alarms. These act as a maintenance guide for the entire vessel for the client, so as to optimise its use.

The yard has also planned remote maintenance. The MARINELEC monitoring system is a perfect match for today’s connected vessels. For ODC Marine, the marine electronics company is moving towards information management in leaps and bounds. “Remote connection enables the pilot to be guided from the bridge in the same way that we would call on the services of a technician for the office computer. This is even more critical for electric and hybrid boats “explains Stéphane Gonnetand. “When there is a bank of 90 to 120 batteries, the monitoring system plays an essential role in accurate prognosis and safety. We monitor a lot of information which is not possible for the naked eye!”

Towards autonomous ships ?

Electric and hybrid ships call upon new technologies which require more extensive prognostics to prolong their in-service life and anticipate premature wear. Centralising information can be taken a step further by an analytical system such as MARINELEC’s ECOMER, which enables data to be collected, stored and interpreted, in order to anticipate break-downs, and optimise consumption and maintenance : really get to know your ship.

ODC Marine is further anticipating the future with the idea of going from a connected vessel to an autonomous vessel. Digital technologies will help tomorrow’s pilots enter port, manoeuvre or even carry out certain difficult operations at sea that the crew no longer wish to do. Yards and equipment manufacturers in the naval sector will propose assistance for new services. MARINELEC is working on these future developments alongside industry, bringing in-depth analysis and its expertise.