#Product Trends

TRELLEBORG WELCOMES PIANC YOUNG PEOPLE TO RIDDERKERK FACTORY

The group enjoyed a presentation by Trelleborg Marine Systems'' EMSA Director, Marco Gaal, which detailed the latest developments in rubber technology for marine fenders, and the impact these technical advances have on the understanding of fender performance and lifecycle.

Key to the organisation of the event was Alfred Roubos, Project Leader at the Port of Rotterdam. Mr Roubos commented: “The event was a great success, with attendees coming from all over the world, including Belgium, Iceland, Spain and as far away as Brazil and Argentina.”

Mr Roubos presented some preliminary findings from PIANC Working Group 145, which is focused on updating PIANC guidance on berthing velocities and fender design. The objective of the Working Group is to produce a report providing data on actual recorded vessel approaches, under a range of environmental conditions, with a view to providing clear guidelines to designers on appropriate vessel design speeds.

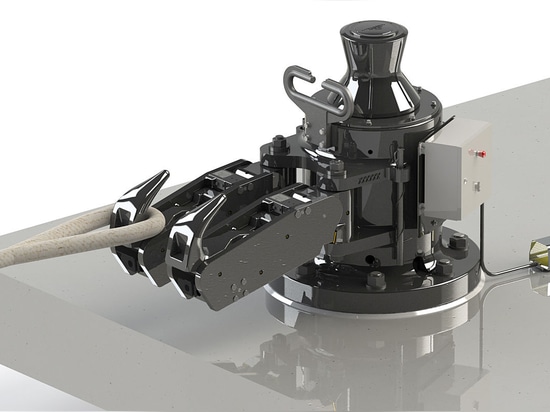

As part of the Working Group, both Alfred Roubos, Marco Gaal and Leon Groenewegen have been extensively involved in research at the Port of Rotterdam in to actual berthing speeds. Data for the study has been recorded by taking measurements of both speed and angle of approach, using Trelleborg Marine Systems'' Smartdock LITE.

Over 100 berthing speed measurements have been carried out at the Port of Rotterdam, which will give the Working Group an enormous amount of data to work with. Data from ports in the US, Germany and Spain has also been recorded to feed in to the study.

On the 21st May, the group were also given a tour of Trelleborg''s Ridderkerk factory, to see how many of Trelleborg''s polymer-based products are manufactured.

Feedback from attendees on the event was extremely positive, with many especially interested in the presentation on the latest in rubber technology.

Marco Gaal, EMSA Director at Trelleborg Marine Systems, said: “It was great to see the enthusiasm of the group and impressive to see how they placed so much importance on understanding the need for quality when specifying polymer-based products. It was a pleasure to host the visit, and we very much look forward to the next one.”