#Industry News

SANDWICH PANELS, THE GREEN OPTION

Empowering lightness

How do boats and ships get built?

Sandwich panels have been introduced in modern shipbuilding, in order to develop more performing and efficient boats both from an energy consumption and a weight reduction point of view.

A sandwich structure is nothing more than a composition of different materials in order to enhance the best mechanical properties of its components.

Implementing the sandwich technology into a boat means aiming at stiffness to weight ratio structural rigidity and dimensions. In fact, the weight difference can vary from 10% to 40%, depending on the materials used. In the nautical sector, this means safer and more performing boats.

For these reasons, sandwich panels are increasingly being used in the construction of hulls, decks, internal reinforcements such as bulkheads, but also doors, floors, furnishings and much more.

Moreover, some sandwich panels are also thermal and acoustic insulators, interesting properties for boats and ships, subjected to the sound of crashing waves and humidity in order to foster a comfortable navigation.

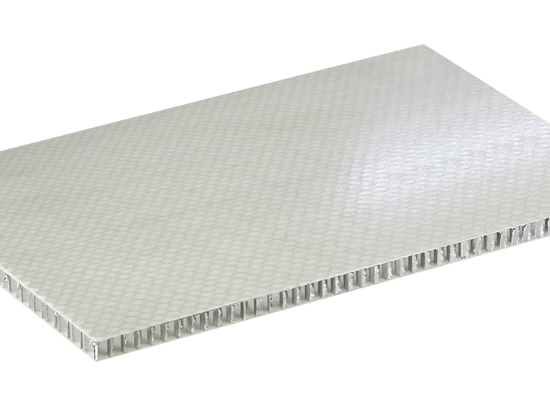

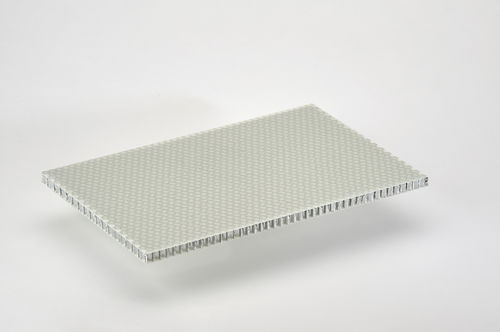

A sandwich structure is composed by different layers. The cores might be either made of foam or of a honeycomb structure, depending on customer’s need and the external skins in different materials. However, despite all the interesting features of these materials, their disposal always represented a big obstacle.

Nowadays, in a few cases, depending on the material, sandwich structures can either be recycled or safely disposed. For this reason, shipyards are inclined to build boats with aluminium honeycomb cores, such as COMPOCEL AL (completely in aluminium, therefore recyclable), or as an ALUSTEP (with skins in fiberglass and aluminium core) or with a recycled foam core in PET such as PETSTEP.