#Industry News

Key points of waterproof design for Marine multi-functional displays

The waterproof design of Marine multi-functional displays needs to meet the strict requirements of the Marine environment and should be comprehensively considered from multiple dimensions such as structural design, material selection.

I. Waterproofing of the front and rear shells

1. Material selection

Use corrosion-resistant metals (such as anodized aluminum) or reinforced nylon, and weld or tightly interlock the seams.

2. Sealing structure

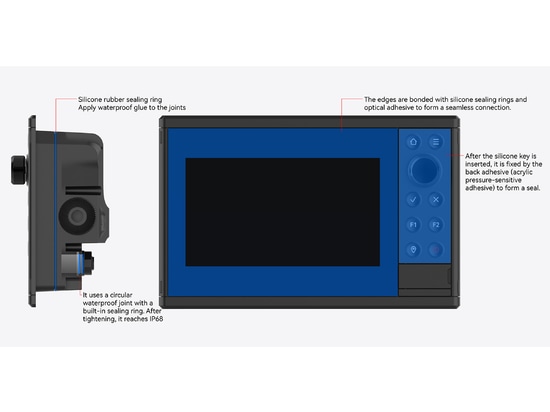

(1) The edge of the shell is made with a concave-convex stepped fit (such as mortise and tenon structure), and a silicone rubber sealing ring is embedded in the middle (with a wire diameter of 2-3mm and a compression of 30%).

(2) Use waterproof screws with rubber gaskets for the screw holes, or add small sealing rings on the inner side.

3. Auxiliary waterproofing

The edges of the internal circuit board are sealed with glue (such as epoxy resin), and waterproof glue is applied to the outside of the shell joints.

-------------------------------------------------

II. interface waterproofing

1. Connector selection

Use the M series circular waterproof connector or the rectangular socket with a lock (such as the DEUTSCH DT series), which comes with a sealing ring and reaches IP68 after being tightened.

2. Cable penetration treatment

Seal the cable by tightening the cover with a metal gran head and a rubber sealing sleeve. The internal weld points are wrapped with heat shrink tubing and waterproof putty.

3. Protection of active interfaces

Idle interface cover waterproof plugs, commonly used interface plus flip cover waterproof covers (with sealing rings).

-------------------------------------------------

III. Screen water resistance

1. Install the seal

The screen is embedded in the front shell by ≥5mm, and the edges are bonded with silicone rubber sealing rings and optical adhesive to form a seamless connection.

(2) The touch screen uses a full lamination process (such as OCA glue) to prevent water vapor from entering the interlayer.

2. Surface protection

The glass is sprayed with a nano-hydrophobic coating to reduce the adhesion of water droplets. It is equipped with an anti-fog heating film inside (automatically heats up when it is damp).

3. Edge reinforcement

The screen is surrounded by TPE soft rubber (with a thickness of ≥2mm) for elastic sealing and vibration buffering.

-------------------------------------------------

IV. Keys are waterproof

1. It adopts an integrally formed silicone key, with the key and the sealing ring designed as one (a ring-shaped sealing ring extends from the bottom of the key), and is embedded in the key hole of the front shell.

2. The edge of the key hole is set with a hook-shaped groove. After the silicone key is inserted, it is fixed by ultrasonic welding or back adhesive (acrylic pressure-sensitive adhesive) to form a seal.

-------------------------------------------------

V. Core Points

1. Material matching: The sealing ring, glue and shell material are compatible to prevent aging and cracking.

2. Easy maintenance: The detachable components (such as joints and sealing rings) are designed with a quick disassembly and assembly structure.

3. Compliance: Complies with Marine electronic equipment standards (such as IMO regulations) and has been certified by classification societies.