#Industry News

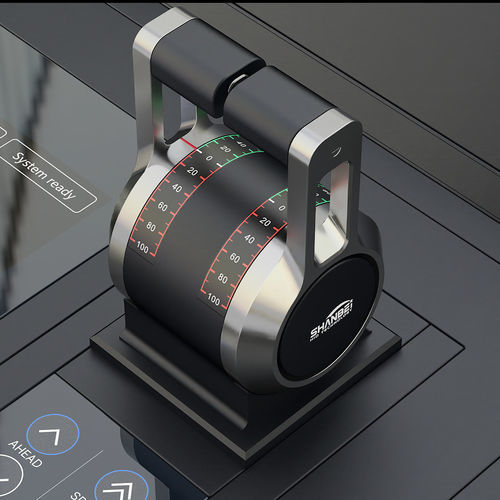

Material of Marine control lever

The selection of materials for ship control handles needs to comprehensively consider multiple factors such as the usage environment, operational performance, durability, safety and ergonomics.

I. Core Performance Requirements

1. Anti-corrosion:

It can adapt to the high humidity and salt spray environment of ships. Especially in open-air or oceanic scenarios, it is necessary to focus on preventing rust and aging.

2. Strength and wear resistance:

Frequently operated handles (such as main propulsion and steering gear handles) need to withstand mechanical loads to avoid breakage or surface wear.

3. Grip comfort:

The material should be anti-slip and sweat-absorbent to prevent discomfort caused by temperature conduction in metal materials (such as being too cold in winter or too hot in summer).

4. Safety and environmental protection:

Comply with maritime flame retardant standards (such as IMO requirements), and give priority to low-smoke, non-toxic and recyclable materials.

---------------------------------------------------------------

II. Common Material Characteristics and Applicable Scenarios

1. Metal material

(1)Stainless steel (such as 316L, 304) :

It has extremely strong corrosion resistance and high strength, making it suitable for high-load and high-corrosion scenarios (such as main control handles, outdoor deck equipment), but it is heavy, has strong thermal conductivity, and has a poor hand feel in winter.

(2) Aluminum alloy (such as 6061-T6) :

Light in weight and easy to process, surface treatment (such as anodizing) is required to enhance corrosion resistance. It is suitable for indoor non-critical handles or lightweight demand scenarios (such as auxiliary equipment control).

(3) Copper alloy:

It has good wear resistance and resistance to seawater corrosion. It is often used for decorative or low-speed wear-resistant handles of traditional ships, but it is heavy and requires regular maintenance.

2. Polymer materials

(1)Engineering plastics (ABS, nylon PA) :

Lightweight, low-cost, and easy to mold, they are suitable for indoor low-load scenarios (such as buttons and handles of electronic devices), but have relatively low strength (requiring glass fiber reinforcement), and are prone to aging when exposed to long-term sunlight.

(2) Rubber/elastomers (nitrile rubber, TPE) :

They have excellent anti-slip properties and good elasticity. They are often used as the outer layer of the handle handle or anti-slip components (such as the anti-slip cover of the steering gear handle), but their strength is insufficient when used alone and they need to be combined with metal/plastic frames.

3. Composite materials

(1)Carbon fiber reinforced materials:

They are of high strength and extremely light weight, suitable for lightweight handles of high-end yachts or racing boats, but they are extremely expensive and complex to process.

(2) Glass fiber reinforced plastic:

It offers high cost performance and moderate strength, making it suitable for non-critical handles of economy ships (such as cabin ventilation risk control systems).

---------------------------------------------------------------

III. Key Principles for Selection

1. Environmental priority: Choose stainless steel or rubber materials for Marine or open-air scenes; For indoor dry environments, engineering plastics or aluminum alloys can be selected.

2. Load matching: Metal materials are used in high-load scenarios (such as the main handles of large ships); Plastic for low-load scenarios (such as electronic adjustment buttons).

3. Hand feel optimization: The combination of "hard frame + soft grip" (such as metal/plastic main body + rubber/TPE anti-slip layer) is adopted to enhance the comfort and anti-slip performance of the grip.

4. Cost balance: For mass production, injection-molded plastics are preferred to reduce costs. High-end or key components are made of a combination of metal and rubber, balancing performance and durability.

---------------------------------------------------------------

IV. Typical Combination Schemes

1. Stainless steel frame + rubber handle: It is used for the main helmsman handle or lifeboat control handle, which is corrosion-resistant and anti-slip, suitable for high-frequency operation in Marine scenarios.

2. Aluminum alloy main body + TPE anti-slip layer: Suitable for yacht cockpit handles, lightweight and comfortable to the touch, combining aesthetics and practicality.

3. Glass fiber reinforced nylon one-piece molding: Electronic equipment handles for small and medium-sized ships (such as radar adjustment handles), economical and wear-resistant, suitable for mass production.