#Product Trends

Luminescence scheme: Application of cold light films

Cold light films are based on electroluminescence technology. They achieve uniform surface luminescence by exciting phosphors (such as zinc sulfide) with an electric field. During luminescence, almost no heat is produced, hence the name "cold light".

I. Core Characteristics

1.Advantages of cold light sources: When emitting light, the surface temperature is close to room temperature (without thermal radiation), making it suitable for temperature-sensitive scenarios (such as medical equipment and precision instruments).

2. Light, thin and flexible: The thickness is usually ≤0.5mm, which can be bent and adhered to curved surfaces (such as arcs and cylinders), meeting the requirements of irregular design.

3. Uniform and soft luminescence: Surface luminescence mode, no glare or obvious light spots, uniformity can reach over 85%, and a matte effect can be customized.

4. Low power consumption and long lifespan: Extremely low power consumption (≤0.8mW/cm²), half-lifespan (with brightness halved) of 3,000 to 10,000 hours, and up to 40,000 hours with special packaging.

5. Environmental protection and safety: Free of harmful substances such as mercury. Some products have passed RoHS certification and are suitable for both indoor and outdoor environments.

-----------------------------------------------------------------------------------------------

II. Basic Structure

It usually consists of five layers from the inside out:

1. Base material layer: Transparent PET/PC/ glass, etc., supporting the overall structure and allowing light to pass through;

2. Conductive layer: ITO (indium tin oxide) or carbon paste, for current transmission (an external high-frequency inverter is required);

3. Luminescent layer: An organic polymer containing phosphor that emits light when excited by an electric field;

4. Insulating layer: Isolates the conductive layer from the light-emitting layer, optimizes the electric field distribution, and prevents short circuits;

5. Protective layer: UV-curable ink or moisture-proof adhesive film to enhance weather resistance and mechanical strength.

-----------------------------------------------------------------------------------------------

III. Main Application Fields

1.Consumer electronics and wearable devices

(1)LCD backlight modules for mobile phones, tablets and laptops (replacing traditional LED backlight, thinner and lighter);

(2) Flexible display screens and breathing lights for smartwatches and bracelets;

(3) Keyboard backlighting and e-book reader lighting.

2. Automobiles and Transportation

(1) Dashboard backlight, interior ambient lighting (bendable to fit the interior curved surface);

(2) Vehicle-mounted identification and emergency escape signs (stable operation in low-temperature environments);

(3) Dynamic bus/subway stop signs, outdoor traffic signs (low power consumption and long service life).

3. Architecture and Decoration

(1) Indoor backlight walls and ceiling edge lighting (uniform and soft, creating an atmosphere);

(2) Art installations in hotels and commercial Spaces (such as dynamic light and shadow murals and irregular-shaped lamps);

(3) Smart home dimmable glass (combined with electrical control technology to achieve the switching between light transmission and light emission).

4. Industry and Healthcare

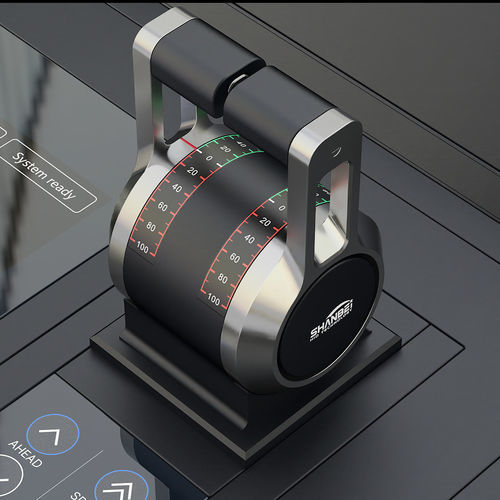

(1)Backlight display of instruments, meters and control panels (low power consumption, anti-interference);

(2) Auxiliary lighting for medical equipment (such as cold light supplementary lighting for surgical lamps to prevent tissue temperature rise);

(3) Low-power indicator lights for aerospace equipment.

5. Advertising and Media

(1)Ultra-thin light boxes and flexible advertising screens (with a thickness of only millimeters, can be attached to curved walls);

(2) Dynamic signboards for concerts and sports events (lightweight and easy to install, supporting custom patterns).

-----------------------------------------------------------------------------------------------

IV. Technological Development Trends

1. Greater flexibility: Utilizing base materials such as PI (polyimide), develop foldable and stretchable cold light films, which are applied in smart clothing, electronic skin, and wearable devices.

2. Higher performance:

(1) Introduce quantum dots/nanomaterials to enhance luminescence efficiency (higher brightness, purer color, color gamut coverage exceeding 110% NTSC);

(2) Optimize the phosphor formula, reduce the use of heavy metals, and enhance the temperature and moisture resistance at the same time.

3. Intelligent integration: Integrate sensors and drive circuits to achieve dynamic dimming (such as automatically adjusting brightness according to ambient light) and pattern transformation, adapting to Internet of Things (IoT) scenarios.

4. More environmentally friendly:

(1) Promote water-based coatings and solvent-free production processes to reduce energy consumption and pollution;

(2) Develop recyclable substrates to reduce electronic waste.

-----------------------------------------------------------------------------------------------

V. Current Challenges and Directions for Improvement

1.Balance between brightness and lifespan: High-brightness scenarios (such as outdoors) will accelerate the attenuation of phosphors. Therefore, the lifespan needs to be extended through constant current drive circuits and moisture-proof packaging technology.

2. Insufficient outdoor visibility: The brightness contrast is low under direct sunlight. Anti-glare films can be stacked or the driving voltage/frequency can be increased (but power consumption needs to be controlled).

3. Drive circuit dependence: A dedicated high-frequency inverter is required (to convert the mains power to AC40V-220V, 50Hz-4000Hz). The future goal is to miniaturize and integrate the drive module to reduce installation complexity.

-----------------------------------------------------------------------------------------------

VI. Summary

Cold light films, with their characteristics of being thin, flexible, uniform cold light and low power consumption, have unique advantages in scenarios that require irregular lighting, atmosphere creation and display of precision equipment. With the advancement of material technology and driving solutions, its application will expand from consumer electronics and decorative lighting to wearable devices, smart buildings and other fields, becoming a new type of luminescent material that combines functionality and design sense.