#Industry News

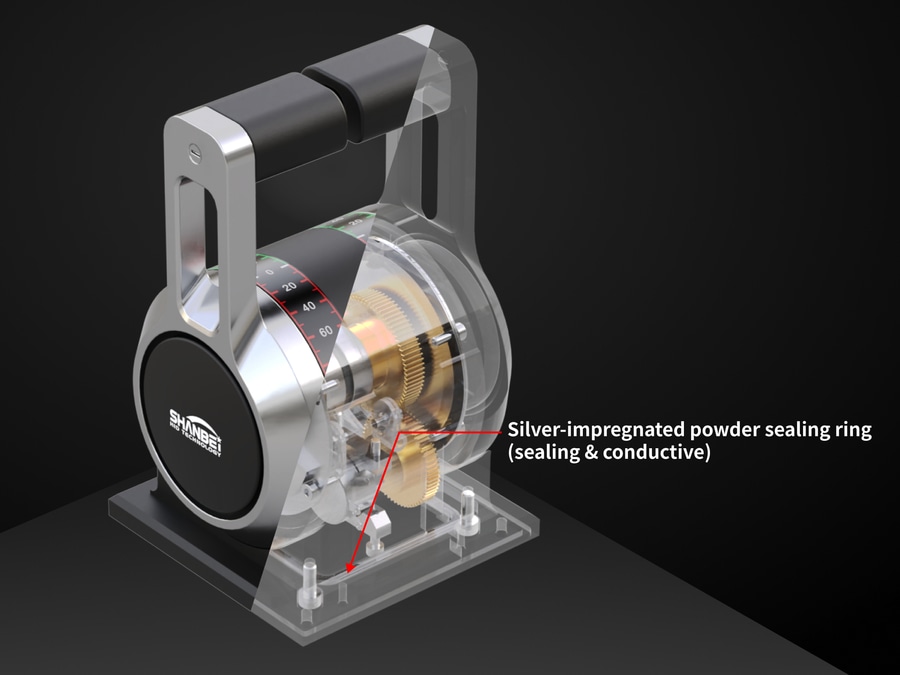

The application of silver powder impregnated sealing rings in the base of Marine control handles

The installation base of the Marine control handle adopts a sealing ring containing impregnated silver powder. Its design combines the special physical and chemical properties of silver with the strict requirements of the Marine environment of ships.

I. Enhance corrosion resistance in Marine environments

1.Resist electrochemical corrosion of seawater:

High concentrations of salts in seawater (such as NaCl) can easily cause electrochemical corrosion of materials, while silver has extremely strong chemical stability and hardly reacts with seawater at normal temperature. The sealing ring impregnated with silver powder can form a barrier through the inert surface of silver, preventing seawater from eroding the sealing ring material and avoiding aging, cracking or sealing failure caused by corrosion.

2. Reduce the risk of galvanic corrosion:

When aluminum alloy (with a relatively negative potential) comes into contact with other metals, it is prone to form galvanic corrosion cells. However, the silver powder in the sealing ring (with a relatively positive potential) exists in a dispersed form, and the sealing ring itself acts as an insulating medium, which can reduce the direct electrochemical contact between the aluminum alloy base and the external metal components, thereby lowering the possibility of galvanic corrosion.

------------------------------------------------------------------------------------

II. long-lasting protection against antibacterial and biofouling

1.The antibacterial mechanism of silver ions:

Silver powder will slowly release trace amounts of silver ions (Ag⁺) in a humid environment. These ions can penetrate the cell membranes of microorganisms, combine with enzymes or DNA within the cells, and disrupt the metabolic functions of microorganisms. They have a significant inhibitory effect on bacteria, algae, shellfish, etc. in seawater. This can effectively prevent material degradation or sealing surface damage on the sealing ring surface caused by the adhesion of Marine organisms (such as barnacles and algae).

2. Reduce maintenance costs:

Traditional sealing rings are prone to biological fouling in seawater environments and need to be replaced frequently. Silver-impregnated sealing rings extend their service life through antibacterial properties, making them particularly suitable for ships that sail for long periods, reducing the difficulty and cost of maintenance at sea.

------------------------------------------------------------------------------------

III. Optimize sealing performance and mechanical durability

1. Improve the fit of the sealing surface:

The fine particles of silver powder can fill the microscopic pores of sealing ring materials (such as rubber and silicone), enhance the material's density, make the sealing surface adhere more closely to the installation base, and reduce the leakage of media such as seawater and fuel. Meanwhile, the addition of silver powder does not significantly reduce the material's elasticity and can maintain sealing stability under working conditions such as ship vibration and pressure fluctuations.

2. Enhance wear resistance:

The friction during the operation of the control handle can cause wear on the surface of the sealing ring. Silver powder, with its high hardness and good wear resistance, can reduce surface grooves or wear caused by long-term friction and maintain the integrity of the sealing surface. It is suitable for Marine equipment that operates frequently.

------------------------------------------------------------------------------------

IV. Dual improvement in heat conduction and anti-aging performance

1. Efficient heat conduction delays material aging:

Silver is the metal with the highest thermal conductivity (about 420W/m · K). The silver-impregnated powder sealing ring can quickly dissipate the heat near the installation base (such as the temperature rise during motor operation or high ambient temperature), preventing the rubber of the sealing ring from hardening and cracking due to long-term high temperature. It is especially suitable for tropical sea areas or high-load working conditions.

2. Resistance to ultraviolet rays and oxidative erosion:

Silver powder has a reflective effect on ultraviolet rays, which can reduce the polymer chain breakage (photo-oxidation aging) of the sealing ring caused by sunlight exposure. Meanwhile, the antioxidant property of silver can inhibit the reaction between the material and oxygen, thereby prolonging the service life of the sealing ring.

------------------------------------------------------------------------------------

V. Compatibility Design with Aluminum Alloy Substrates

1. Chemical and thermal compatibility:

Silver does not have a vigorous chemical reaction with aluminum alloy. After the formula of the sealing ring material (such as silicone rubber, fluorine rubber) is optimized, its coefficient of thermal expansion is close to that of aluminum alloy, which can avoid the increase of the sealing surface gap due to temperature changes.

2. Mechanical performance matching:

The elastic modulus of the sealing ring matches the rigid support of the aluminum alloy base, which can maintain a stable sealing pressure in the vibrating environment of the ship and avoid sealing failure caused by vibration.

------------------------------------------------------------------------------------

VI. Summary: Core Application Value

The silver powder-containing sealing ring, with its triple advantages of "corrosion resistance and antibacterial + long-lasting sealing + environmental adaptability", has solved the sealing problems of ships under complex working conditions such as seawater corrosion, biological fouling and mechanical vibration. Compared with traditional sealing rings, it has significantly improved reliability and service life, and is a key technical solution in Marine engineering that takes into account both performance and economy.