#Product Trends

The description of Engine control lever

The main engine propulsion control handle of a ship, as the core interaction device between the bridge and the propulsion system, is mainly used to adjust the propulsion direction, control the rotational speed and power, etc.

I. Main Types and Characteristics

1. Mechanical hydraulic type: The hydraulic valve is connected through a mechanical connecting rod or steel wire rope. It is purely physical transmission, does not require electricity, has high reliability, and is suitable for emergency working conditions. However, the operation feels heavy and can easily cause fatigue. The installation space requirements are high, and mechanical wear will affect the accuracy. It is commonly seen in old ships, small fishing boats, etc.

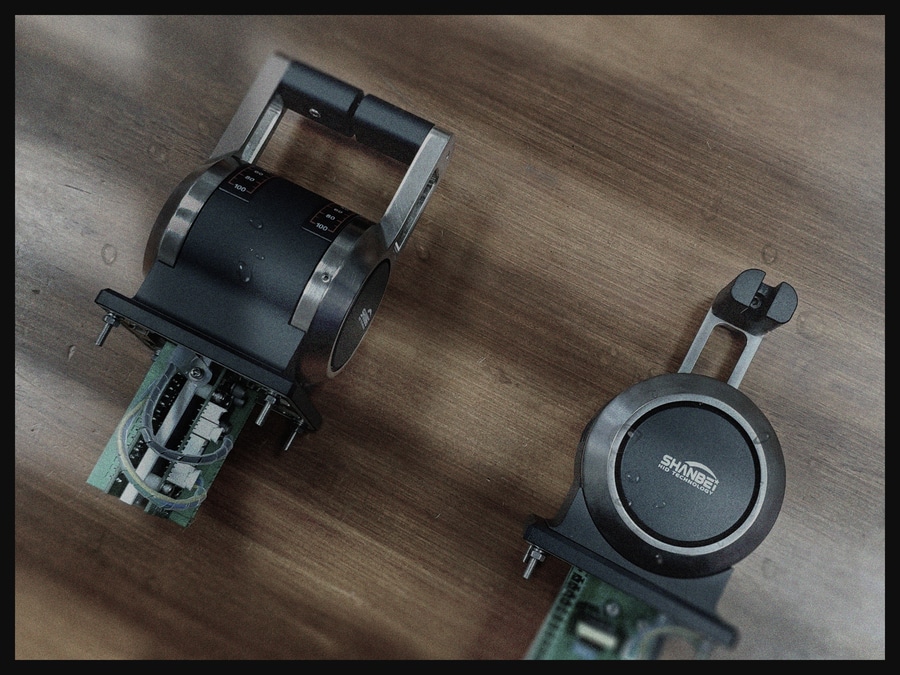

2. Electro-hydraulic type: The handle is equipped with a potentiometer or encoder inside, which converts the operation signal into an electrical signal and then drives the main unit through an electro-hydraulic valve. It is easy to operate, supports remote control, has a feedback mechanism, and can synchronize the status of the controller and the main unit. However, relying on the hydraulic system, there is a risk of oil leakage. In low-temperature environments, the viscosity of the hydraulic oil will affect the response speed. It is often used for the main propulsion control of medium-sized merchant ships.

3. Electronic (digital) type: It adopts a fully electronic design and sends digital signals to the host controller via CAN bus or network protocol. The digital transmission has high accuracy, supports multi-handle synchronous control, and integrates intelligent functions such as anti-misoperation lock and automatic speed limit. However, it relies on power supply and communication, and requires a dual-redundancy design, which is suitable for modern ships or automated integration scenarios.

---------------------------------------------------

II. Key Points of Design and Performance

1. Operation feel and feedback: It is divided into gear type (with clear positioning, suitable for precise gear control) and stepless speed regulation type (linear regulation, suitable for smooth speed change). Provide operation feedback through mechanical damping or electronic vibration, sound and light prompts.

2. Environmental adaptability: The protection grade of the cab handle should reach IP54, and that of the open-air deck handle should reach IP66. Meet the anti-vibration/shock standards, adapt to the temperature range of -20 ℃ to 70℃, and special areas need to be equipped with heating or heat dissipation functions.

3. Safety redundancy design: Equipped with an emergency handle independent of the main control system; Set up protection against misoperation such as reversing interlock and emergency stop button; It adopts a dual handle backup of the driver's console and the wing axle.

---------------------------------------------------

III. Selection Suggestions and Development Trends

1. Selection suggestion: For reliability, choose the mechanical hydraulic type. For automation and precision, choose the electronic type. Balance cost and maintenance by choosing the electro-hydraulic type.

2. Development trend: Integration with touch screens, built-in display screens on controllers; Supports gesture control and is compatible with wearable operation devices; Apply lightweight materials such as carbon fiber to reduce operational fatigue.