#Product Trends

The key design points of Engine control lever (boat)

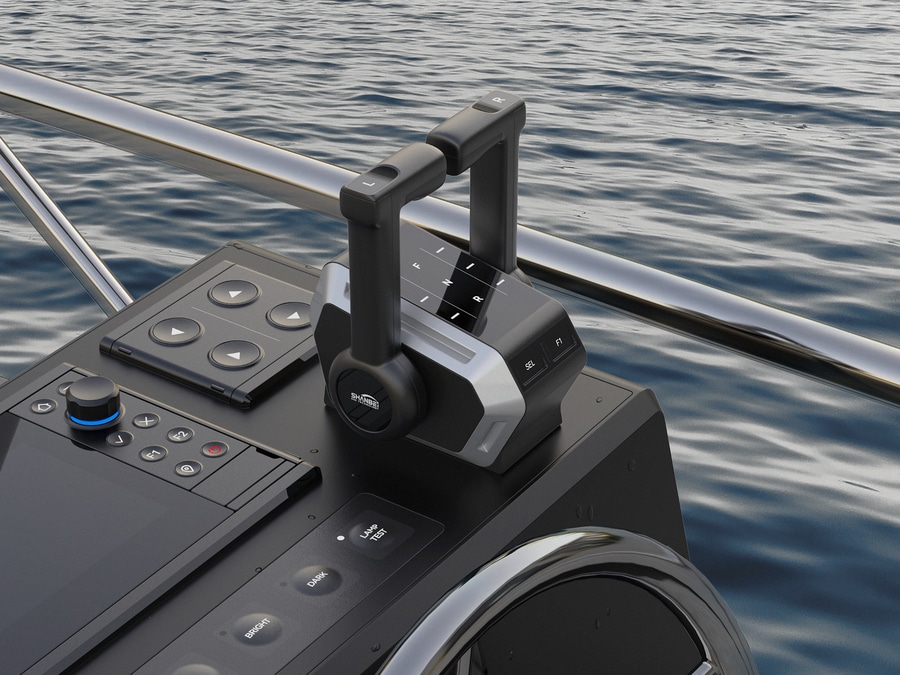

The design of the propulsion control handle for the yacht's main engine needs to take into account multiple aspects such as operational convenience, control accuracy, and safety to ensure the stability and safety of the yacht's navigation.

I. Ergonomic Design

1. Comfortable grip: The shape of the handle should conform to the structure of the human hand, facilitating crew members to hold it for a long time. Anti-slip materials such as rubber can be used to increase friction. For example, the handle of the Caterpillar MPC 100 yacht propulsion control system is ergonomically designed and can be comfortably held in any direction.

2. Easy operation: According to the layout of the bridge and the operation habits of the crew, the installation Angle and height of the handle are reasonably determined to ensure that the crew can operate easily with their arms naturally extended when sitting or standing. At the same time, it is considered that the handle can be used in both top-mounted and reverse-mounted postures to adapt to the operational preferences of different crew members.

------------------------------------------------------

II. Functional Design

1. Precise speed regulation: By outputting an electrical signal proportional to the rotation Angle of the handle to the engine control unit (ECU), the engine speed is precisely controlled, enabling the yacht to move forward, backward and idle.

2. Auxiliary functions: Auxiliary output functions can be set, such as engine stop/start, stern propeller and rudder control, etc., facilitating crew members to perform multiple operations on one handle and improving driving efficiency.

------------------------------------------------------

III. Control Accuracy Design

1. Sensor selection: High-precision sensors, such as magnetic Angle sensors, are selected to accurately detect the position and movement of the handle, converting them into precise electrical signals to ensure that the yacht can precisely respond to the crew's operational intentions.

2. Customizable Settings: Damping and positioning Settings can be customized to meet the personalized operation needs of different crew members, and also adapt to different sea conditions and navigation scenarios.

------------------------------------------------------

IV. Durability Design

1. Material selection: The main body of the handle is made of high-strength and corrosion-resistant materials, such as stainless steel and aluminum alloy, to adapt to harsh environments like dampness and salt spray on the yacht. The internal electronic components should have good waterproof, moisture-proof and anti-vibration performance.

2. Structural reinforcement: The connection parts of the handle should be firm and reliable, capable of withstanding certain external force impacts. For instance, wear-resistant bearings or bushings can be used at the joints to increase the service life of the handle.

------------------------------------------------------

V. Feedback Design

1. Haptic feedback: Rubber buttons can be equipped with metal domes to provide clear haptic feedback, allowing crew members to clearly know whether the operation is being performed. A damping device can also be set up to generate frictional force related to the throttle opening during the rotation of the handle, allowing the crew to know the throttle status through their sense of touch.

2. Visual feedback: It can be equipped with a backlit display screen to show information such as engine speed and yacht speed, ensuring safe operation at night. The operation status of the handle can also be intuitively understood by the crew through the position indication of the LED light strip.

------------------------------------------------------

VI. Safety Design

1. Misoperation protection: The buttons adopt an inwardly concave design, etc., to prevent accidental touch. When setting up the safety switch, it must be compatible with the safety key to ensure that only authorized personnel can operate the handle and guarantee driving safety.

2. Limit protection: Design a limit device to restrict the rotation range of the handle, preventing equipment damage or safety accidents caused by excessive rotation.