#Industry News

How to cut advanced composites (no CNC)

Cutting composites without a CNC machine

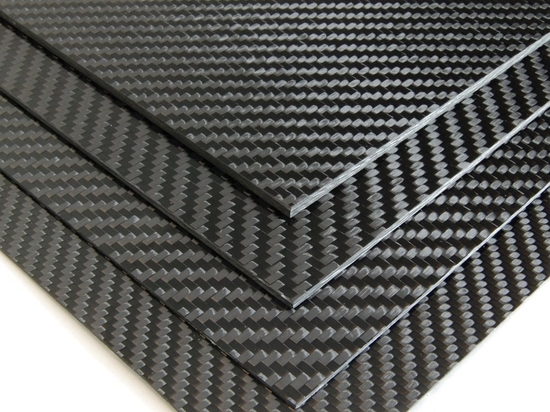

Moulded composite sheets present few health hazards compared with manufacturing the composite in the first instance because there is no exposure to toxic chemicals, solvents, liquid resins or dry fibres that are necessary for the moulding process. However, there are some simple safeguards that you should observe when cutting and finishing your moulded composite sheet. The dust generated during cutting your carbon fibre composite sheet is not toxic but can be mildly irritating to your skin, eyes and lungs.

We do recommend that you wear gloves, overalls and safety goggles to protect you skin and eyes whilst using a suitable high quality dust mask to prevent breathing in the dust generated by cutting, sanding and finishing. If possible have extraction and a fresh air supply to your working area. Working safely should always take priority in any task you do and by following health and safety guidelines for working with carbon fibre you will ensure that your risk of injury is minimised. For finishing the edge to be smooth, clean and shiny – progressive use of wet and dry silicon carbide papers are very effective and produce less dust when used wet.

BLADE AND TOOLS FOR CUTTING CARBON FIBRE COMPOSITES

Depending on the thickness of sheet you have purchased you can safely cut carbon fibre with a variety of tools ranging from sharp scissors, scalpels and rotary cutters for our ultra-thin sheets (<0.5 mm). For thicker sheets abrasive type cutting tools generally perform better such as diamond coated blades (for finer cut), tungsten carbide coated discs (roughing out cuts), jigsaw blades (tungsten coated), tungsten coated hacksaw blades, router cutters (composite type). Abrasive type cutting blades are available for manual tools such as hacksaws and electric tools such as Dremel rotary tool (other brands are available), routers, saws, drills and jigsaws.

Drilling holes successfully is best achieved by using a suitable sacrificial backing material such as plywood securely placed underneath the composite sheet. This will help minimise fibre break out and splintering on the underside of your composite sheet. Higher drill speeds work better as does starting off with a smaller diameter drill bits (standard bits for metal drilling) and progressively increase to desired hole diameter. Generally you will cut your composite sheet ‘just’ oversized and finish or sand down to the final dimensions with abrasive sanding tools. There are various options available for this such as tungsten carbide (e.g. Permagrit) sanding blocks that will make quick work of sanding down to your final dimensions, where general purpose sandpaper on a sanding block is also effective.

AFTER CARE TIPS

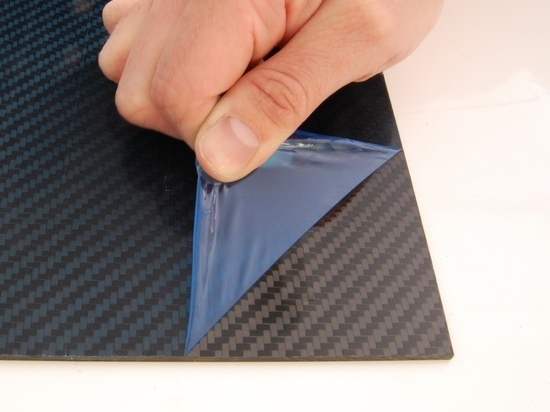

Once you have completed all finishing operations it is time to remove the protective film on the surface that will have acted to guard the gloss finish from scratching. Occasionally the film will leave a slight residue that can be easily removed with automotive glass polish (e.g. Autoglym Glass Polish) applied with a soft polishing cloth. If the sheet is going to be exposed to direct sunlight we recommend spraying a few light coats of standard automotive Ultra Violet (UV) clear lacquer to preserve the flawless surface finish from chalking or ask us about our PREMIUM range carbon fibre sheets with UV protection.