#Industry News

The Advantages of Void Free Carbon Fiber Plate & Billet in Modern Manufacturing

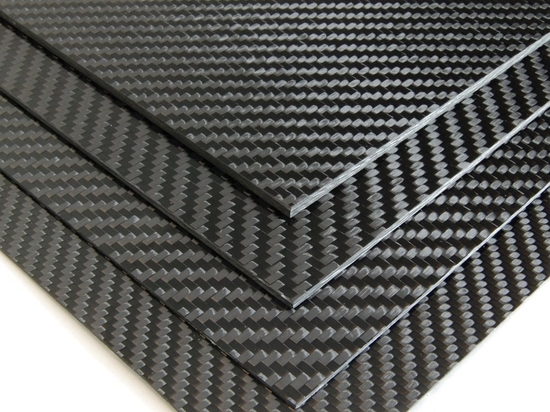

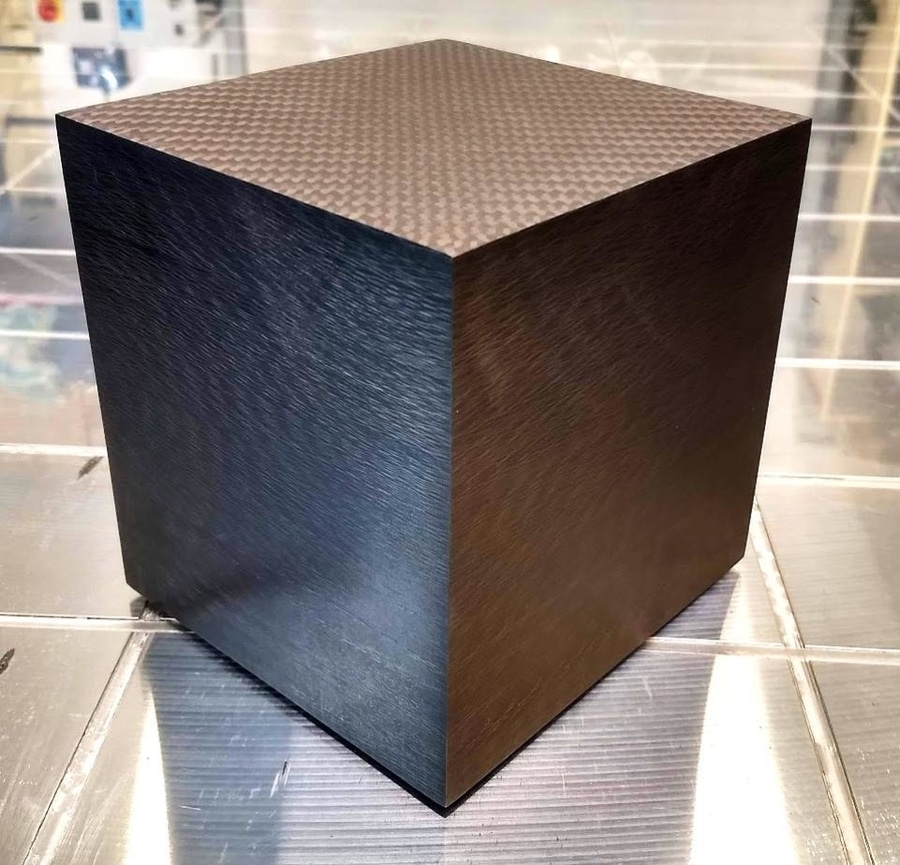

Machining carbon fiber billets

In modern manufacturing, the quest for versatile and lightweight materials has led to significant innovations. Among these innovations, carbon fiber plates and billets have emerged as key players, revolutionising the way engineers and designers create components with precision and efficiency. In this blog, we will explore the numerous advantages of carbon fiber billets & plates in manufacturing, highlighting why it has become the material of choice for a wide range of applications.

The Versatility of Carbon Fiber

When we mention “plate” and, particularly, “billet/block,” the mental image that often comes to mind is that of a solid block of metal. Traditional metallic product forms like billets, blocks, plates, and sheets have long been employed as starting materials for crafting various components through reductive machining techniques such as milling and turning.

Applications Across Industries

One of the standout features of our carbon fiber is its remarkable versatility across a diverse spectrum of industries. Whether you’re involved in medical device manufacturing, drone production, marine engineering, or the automotive sector, these billets seamlessly find their place. They shine in applications characterised by short lead times, frequent design iterations, and lower production quantities. Essentially, carbon fiber plate and billet can be employed in virtually any scenario, with the only constraint being the limits of physical machining.

To find out more about the advantages of Juno Composites’ Plates and Billets please follow the link to the original article.